CA State License 1088433

What is Tempered Glass?

Tempered glass is a type of safety glass designed for strength and durability. Made by heating annealed glass to around 1,150ºF and quickly cooling it through a process called quenching, it becomes up to four times stronger than regular glass.

Uses and Benefits:

Caution:

Choose tempered glass for your home or business to combine safety, style, and reliability. It’s the ultimate solution for modern, secure spaces.

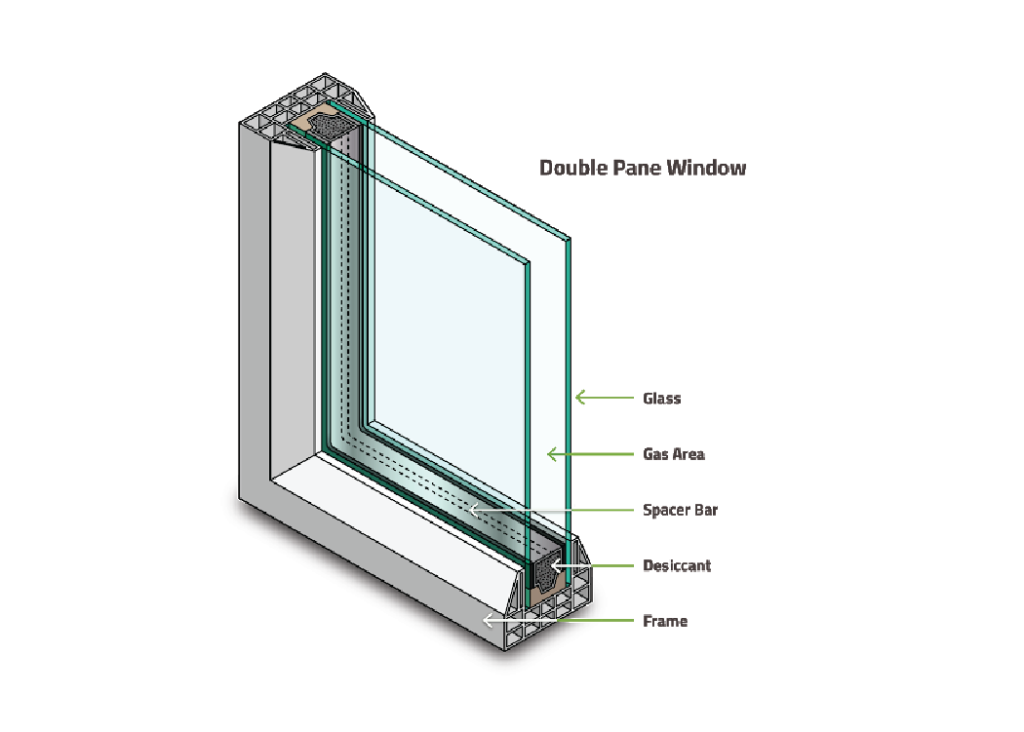

Insulating glass, also known as double-glazing or double-pane glass, is designed for energy efficiency and temperature control. It features two or more layers of glass separated by a vacuum or gas-filled space and sealed around the edges. This design reduces heat transfer, making it ideal for homes and businesses.

Insulated glass units (IGUs) can be incorporated with tempered glass, laminated glass, colored glass, or low-E glass for enhanced performance. They come in various thicknesses, typically ranging from 1/8″ to 3/8″, with special applications allowing for even thicker options.

The lifespan of an IGU depends on factors like material quality, installation location, and maintenance. Most units last 10 to 25 years, but windows facing harsh conditions may have a shorter lifespan of around 10 years.

Choose insulating glass for improved energy efficiency, reduced noise, and a comfortable indoor environment. It’s the perfect solution for modern, eco-friendly buildings.

Laminated glass is typically used for safety or security glass. In case of accidents or break-ins, The glass will hold together from shattering.

It is simply made by sandwiching layers of polyvinyl or interlayer material in between two or more glass layers.

High temperature and pressure are applied in the process to eliminate air bubbles from the glass layers, forming a tough seal. The layers are bonded permanently using both mechanical and chemical bonds.

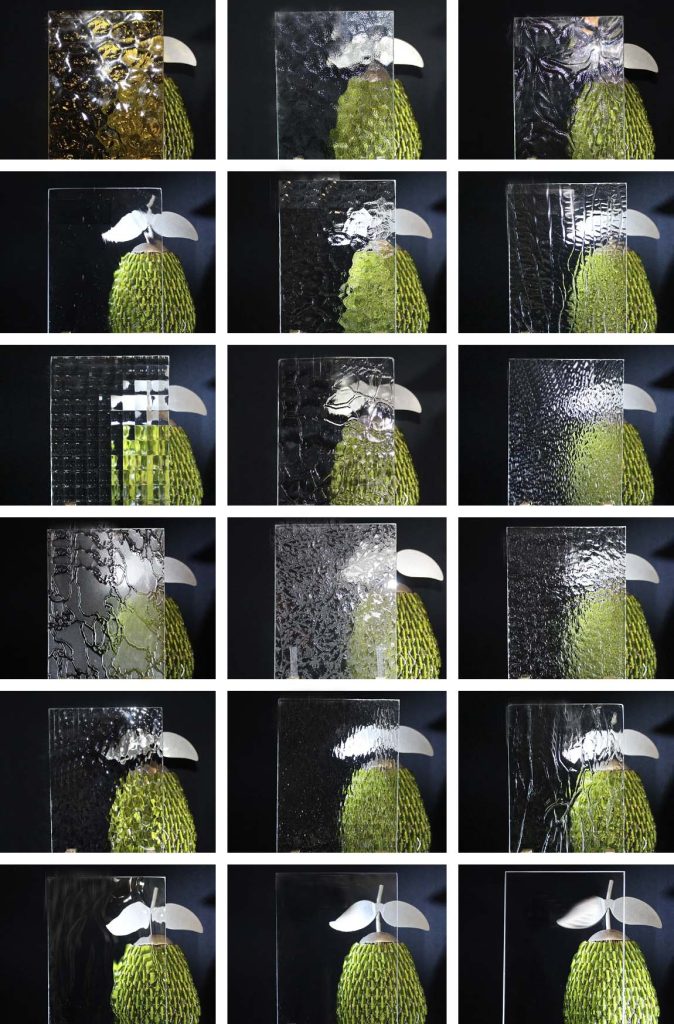

Bay Area Glass and Windows offers a wide variety of patterned, obscure, and textured glass products.

Tempering is available on certain patterns. Choose a pattern you are interested in and call us today for a free quote.

A transparent, solid sheet made of acrylic resins. Some common brand names are Plexiglas®, Perspex, and Lucite®.

Uses:

Acrylic sheets are lightweight, tough, and colorless, with excellent clarity and outdoor weather resistance.

Acrylic sheets are used for safety glass, aircraft canopies, windows, skylights, signs, instrument dials, tail light lenses, lighting fixtures, optical lenses, storage and display cases, and bulletproof glass.

Caution:

Compared to glass, acrylic is lighter and shatter-resistant but more susceptible to scratching and transmission of UV.

Acrylic sheets come in sizes:

1/16″ , 1/8″ , 3/16″ , 1/4″ , 3/8″ , 1/2″ , 3/4″ ,1″ , 1.25″ , 1.5″ , 2″ , 2.5″ , 3″ , 4″

Bay Area Glass and Windows Inc. is your trusted partner for premium glass and window solutions in San Jose CA. Contact us today.